Dry ice cleaning is an ideal system for the Rail Industry, with this innovative technology you can clean all from the electrical panels to the seats:

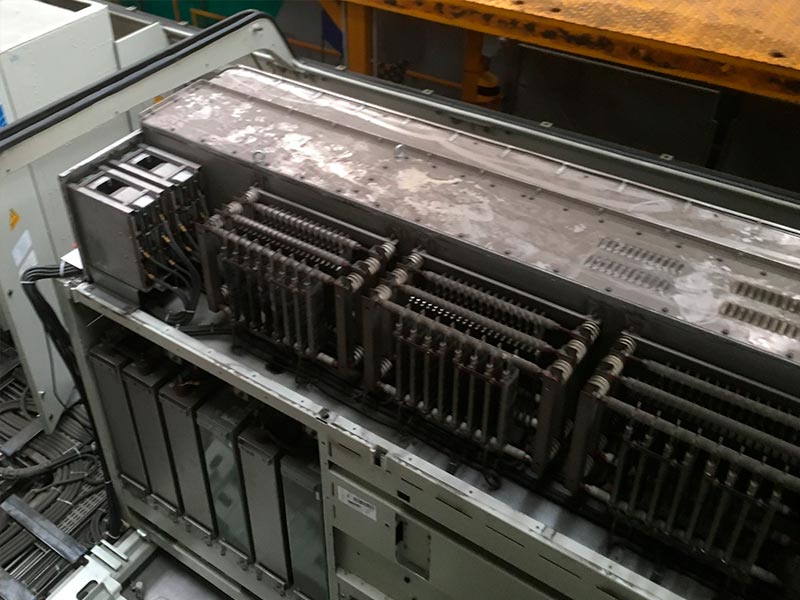

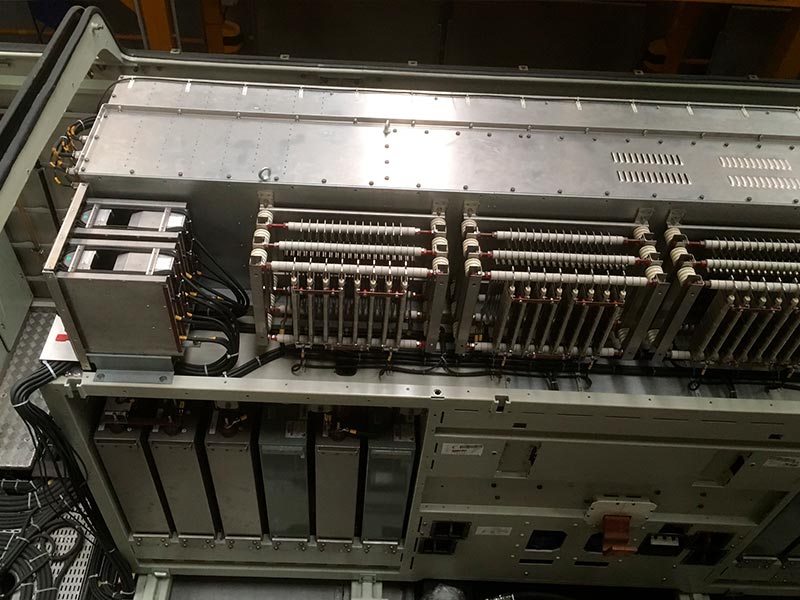

Air conditioning / heating systems.

Racks.

Springs and shock absorbers.

Brake cylinders.

Antilazo devices

Seats

Electrical control boxes

Wires

Some of the many benefits are:

- Reduction of the risk of shortcuts and breakdowns.

- Reduces the risk of damage to components.

- Reduction of labor cost.

GET AN AMAZING RESULT IN NO TIME!

DRY ICE CLEANING WITHOUT WATER OR CHEMICALS.

DRY ICE BLASTING SERVES MANY BENEFITS

- Cleaning with a Natural Substance:Dry Ice Blasting uses Dry Ice Pellets made from the same substance used to carbonate beverages. This method does not generate secondary waste as does sand, soda, water, or grit cleaning. Dry Ice Blasting also replaces chemical and solvent based cleaning.

- Safe on Electrical: This versatile process cleans heavy buildup without damage to sensitive areas like electrical components, switches, wiring, photo electric sensors, and more.

- A Thorough, Deeper Cleaning: Since Dry Ice Pellets manage to reach every nook and corner of the equipment it cleans more deeply and effectively.

- No Damage: Dry Ice Blasting is completely dry, non-abrasive, non-toxic and non-corrosive . It quickly removes most contaminants without damage to switches, panels, lines, tubes, wiring or belts, HVAC equipment and is safe to use on electrical.

- No Down Time: The process is very fast and dry. The dry ice disappears on contact and can be performed on-line without disassembly and without need for drying time.