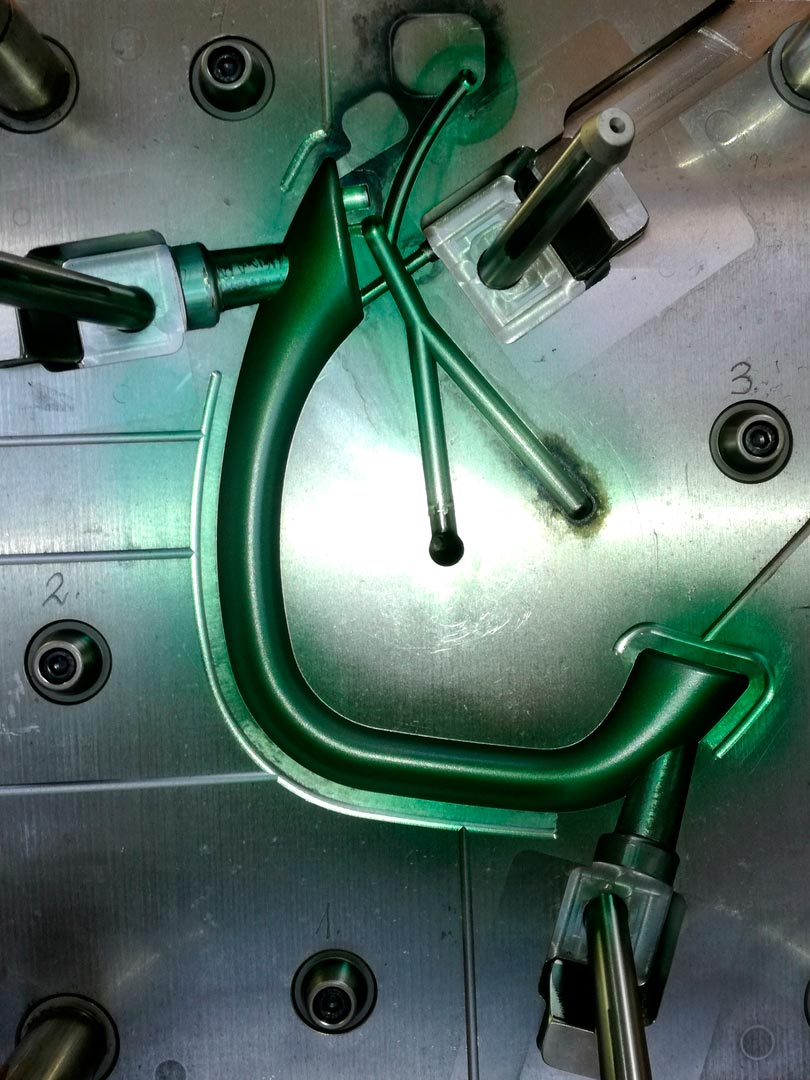

Dry ice blasting is the fastest way to remove a tarnished release agent from inside a plastic injection mould press. It is also the best way to remove 100% of the contaminant, especially in the hard to access valleys and crevices of the tool.

What can be cleaned with dry ice blasting?

Release agents

Overspray

Hardened plastic

Mix of all used materials and substances

Advantages of dry ice blasting in plastic industry:

No damage to mould – longer lifetime – reduced cost

Reduction in Labour cost

Preventing damage to the finished product surface – lowering waste and scrap rates.

No dust.

No water residue.

In site cleaning

Reduced time and labour cost as mould in cleaned in-situ

Dry ice also cleans slots and screen vents at the same time.

No changes in the mold surface dimensions.

Lower rejects as mould is 100% cleaned

Cleans what is not visible

Cleaning with dry ice of moulds, screws, mixers ect. in plastic and styropor injection industries can benefit from dry ice cleaning.

In situ on site cleaning without having to remove the moulds from the plastic injection moulding machine. Cleaning when hot is an advantage to the cleaning with dry ice. Quick return of equipment back into production. No need to cool down and reheat.

What normally could take hours can be done in minutes.

Regular cleaning reduces the time needed for each cleaning operation and more important reduces the rejects to a minimum.

No dust, water or chemicals used to get superior finish and quality.

GET AN AMAZING RESULT IN NO TIME!

DRY ICE CLEANING WITHOUT WATER OR CHEMICALS.

DRY ICE BLASTING SERVES MANY BENEFITS

- Cleaning with a Natural Substance: Dry Ice Blasting uses Dry Ice Pellets made from the same substance used to carbonate beverages. This method does not generate secondary waste as does sand, soda, water, or grit cleaning. Dry Ice Blasting also replaces chemical and solvent based cleaning.

- Safe on Electrical:This versatile process cleans heavy buildup without damage to sensitive areas like electrical components, switches, wiring, photo electric sensors, and more.

- A Thorough, Deeper Cleaning:Since Dry Ice Pellets manage to reach every nook and corner of the equipment it cleans more deeply and effectively.

- No Damage:Dry Ice Blasting is completely dry, non-abrasive, non-toxic and non-corrosive . It quickly removes most contaminants without damage to switches, panels, lines, tubes, wiring or belts, HVAC equipment and is safe to use on electrical.

- No Down Time:The process is very fast and dry. The dry ice disappears on contact and can be performed on-line without disassembly and without need for drying time.