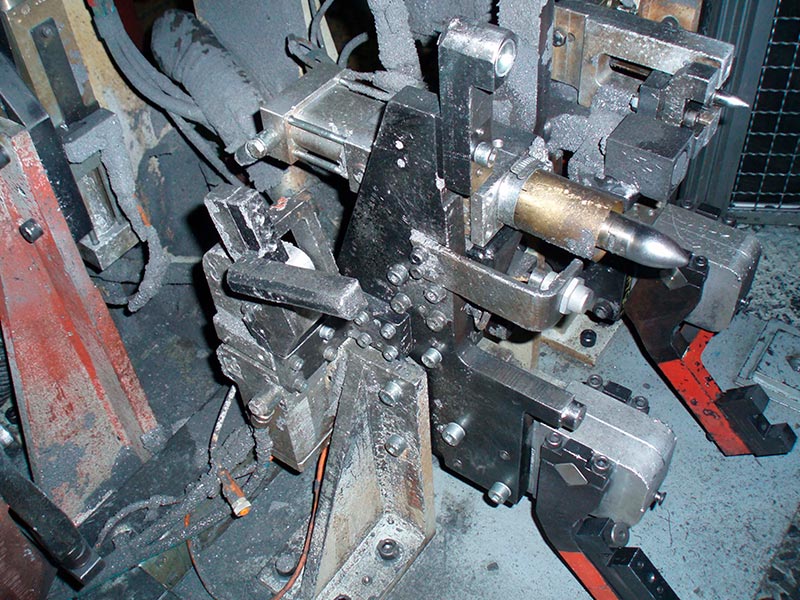

Automotive (Welding cells and robot cleaning)

Critical process cleaning to automotive manufacturing industry.

Regular maintenance of automated production equipment increases the volume and quality required from manufacturing industries. Automated systems are now more efficient than ever, lighter, faster and don’t require visits to the rest room. To that end it is essential that a bespoke integrated cleaning and preventative maintenance program is in place and monitored, to extend the life and service of your assets.

Difficult contaminants produced during production could be, but not limited to, Grease, Carbon, Weld slag, Weld spatter, Resin, Glue and chemicals

All of the above if not regularly removed will build up in and around automated equipment damaging wrist axis joints, clamps and grippers, locating pins and part present sensors and when the equipment fails your very expensive technician will have to remove the build up of slag/dirt before any repair work can be completed.

(extended equipment down time ).

All automated equipment benefits from a “ NO CONTACT CLEANING SYSTEM”. Lightweight materials used to manufacture Gun Heads, Grippers, and Tooling Stations are damaged by traditional methods of Slag and Debris removal.

Dry Ice provides for the removal of problem causing contaminants without damage to the equipment.

Dry Ice Cleaning eliminates scraping, chiseling, hammering, and the use of toxic chemical cleaners. Efficiency is increased due to Grippers, Welding guns, locating pins and tooling stations working as if new, also as and when break downs occur, engineers can isolate and repair defective equipment quickly without having to remove difficult weld slag.